SHENZHEN LANLYN TECHNOLOGY CO., LTD.

Contact :Mr. Zeng

Mobile :13824752050

Mr. Hu

Mobile :18825449055

Email :1134473052@qq.com

rachel@lanlyntech.com

Address: Lanlian Laser Industrial Park, No.51, Shabao 3rd Road, Shajing Street, Baoan District, Shenzhen, China.

Super Mini Laser Spot Welder

Product Descriptions:

The laser spot welding machine dedicated to gold and silver jewelry, golf, fill holes for electronic components, welding trachoma, weld inlay mouth and so on. Welding firm, beautiful, non-distortion, simple operation, easy to use.

LN-200W laser spot welding machine is used for perforation and spot welding of the sand hole for gold and silver jewelry. Laser spot welding is an important application of laser materials processing technology. Spot welding is thermal conduction, namely, the laser radiates the surface of the part, and the heat on the surface expands inside through heat conduction. By controlling parameters such as laser pulse width, energy, peak value and repeating frequency, the part will melt, and thus forming specific molten pools. Due to its unique benefit, the product has been successfully applied to gold and silver jewelry processing, and welding of small-sized parts.

Salient Features:

ü Energy, pulse width, frequency and facular can be adjusted within a wide range to achieve different welding effects. The parameters are adjusted by the control rod in the sealed cavity, simple and efficient

ü Ceramic focusing cavity imported from the U.K. is employed, corrosion resistant, high temperature resistant, efficient in optical/electrical conversion. The focusing cavity's service life is 8 to 10 years, and the service life of the xenon lamp is over 8 million times

ü World-leading automatic light shielding system is employed to remove stimulation of light on eyes during operation

ü 100% Maintenance Free Equipment with 10000 working hours life

ü Personalized design in compliance with ergonomics principles

Advantages

Fast, Efficient, Deep, Little Distortion, Little Affection Area, Quality Welding, Pollution Free Welding Point, and Energy Saver.

Technical Parameters:

Laser Power | 80W/100W/200W |

Laser Wavelength | 1064nm |

Max Pulse Energy | 120J |

Laser Welding Depth | 0.1-2.0mm |

The Pulse Width | 0.1-20ms |

Batter, Laser Welding Frequency | 1-20Hz |

Adjustable Range of Spot Size | 0.2-2mm |

Control System | Industrial Computer |

Machine Power Consumption | ≤4kw |

The Demand for Electricity | 220V±0%/50Hz/30A |

System Components and Environmental System Components | Host Computer, Cold Water Tank |

Supplies | Xenon Lamp, Filter, Protection Lens, (Argon Gas Optional) |

Installation Environment | 4 Square Meters (Installation Area) |

Environment | Clean, No Dust or Less Dust |

Temperature | 55℉ (13℃) to 82℉ (28℃) |

Humidity | 5% to 75% Non-Condensing. |

Power Supply | 220V50HZ Alternating Current, 30A an Air Switch, |

Machine Dimensions (L x W x H) | 88cm x 50cm x 61cm |

Weight (Kg) | Gross Weight 80Kg (Desktop) 140Kg (Floor Type) |

Applicable Materials & Industries:

Jewelry laser welder widely used in aviation, aerospace, sports products, jewelry, golf head, medical instrument, titanium alloy denture, instrument, electronics, machinery, automobile, especially for the perforating of gold and silver jewelry, spot welding, repairing, inlay and welding of the claw.

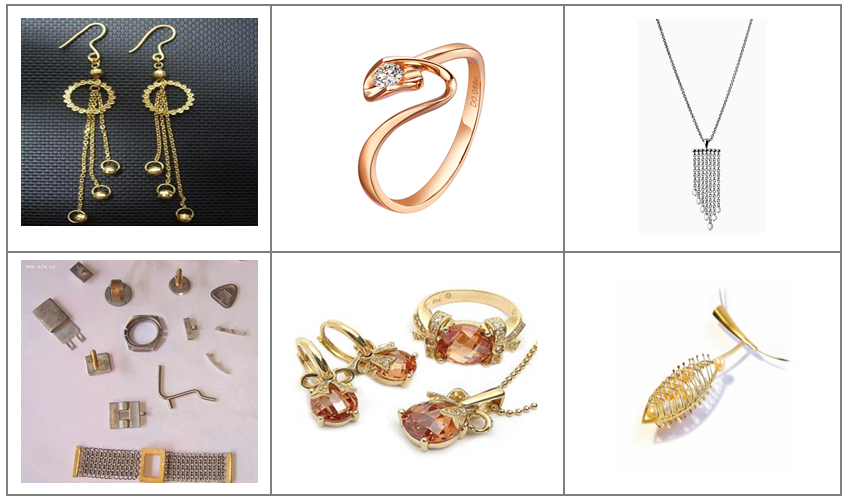

Application Samples: