SHENZHEN LANLYN TECHNOLOGY CO., LTD.

Contact :Mr. Zeng

Mobile :13824752050

Mr. Hu

Mobile :18825449055

Email :1134473052@qq.com

rachel@lanlyntech.com

Address: Lanlian Laser Industrial Park, No.51, Shabao 3rd Road, Shajing Street, Baoan District, Shenzhen, China.

Mould Laser Welding Machine

Product Application:

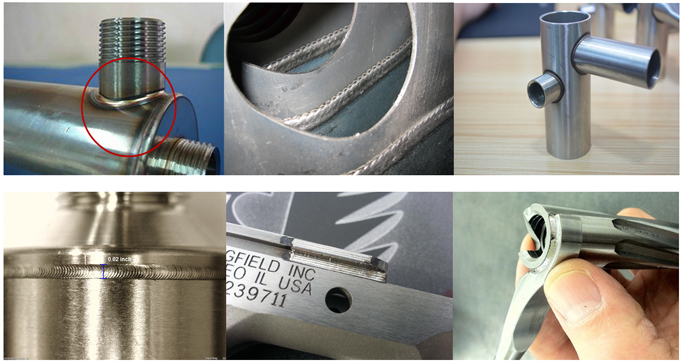

This is laser mould welding workstations specialized for mould repair, for the all tooling steels; With our laser welding system we can carry out modifications and repairing of any moulds and dies, which include: bending tools, recasting tools, cold punching dies, hot runner nozzles, titanium alloys, aluminum mould, Cu-electrodes, and coated surface and the narrow gap, cavity, or the deep hole, which is easy to process by laser welding machine.

Advantages:

Importing the advanced technology from German, using a unique design of overall structure, suitable for various medium and small moulds repairing

Using the ceramic reflectors that import from UK (200W is ceramic reflector and 300/400W is golden laser reflector). It can resist corrosion and high temperature. Its lifetime up to 8-10 years. The xenon lamp lifetime more than eight million times

Small range of heat, the workpiece will not be deformed, no stomata

It can weld in narrow position, welding deeper, and would not hurt the edge and it wouldn’t make the mould deformation

Parameter adjustment using intelligent remote control, operating simply and fast

No need to modify the mould, it can save a lot of material, labor and time costs

It can work 24 hours continuously

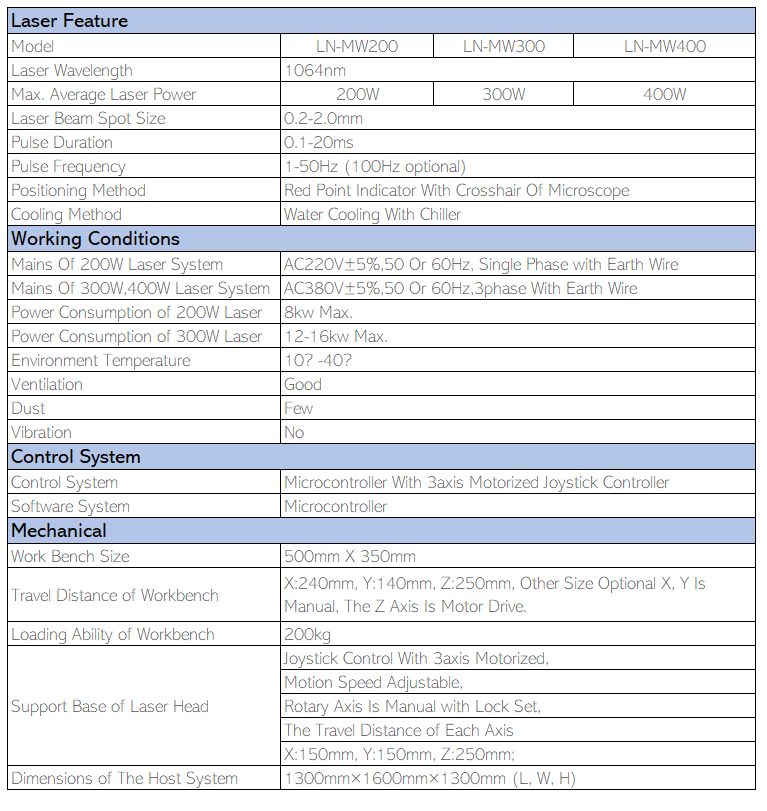

Product Parameters:

Product Application:

It is mainly use in mould & plastic industry, which adopts laser high energy focusing to effectively process tiny broken parts of moulds. Such as: repairing all kinds of mould cracks, small holes, collapse, sealing edge and other tiny parts. It has irreplaceable advantages while compare with traditional welding like high accuracy rate, high speed, depth, strength, no holes after processing, can polish into shining surface after welding, especially suitable to repair mould which require polish.

Application Samples: