SHENZHEN LANLYN TECHNOLOGY CO., LTD.

Contact :Mr. Zeng

Mobile :13824752050

Mr. Hu

Mobile :18825449055

Email :1134473052@qq.com

rachel@lanlyntech.com

Address: Lanlian Laser Industrial Park, No.51, Shabao 3rd Road, Shajing Street, Baoan District, Shenzhen, China.

Product Introduction

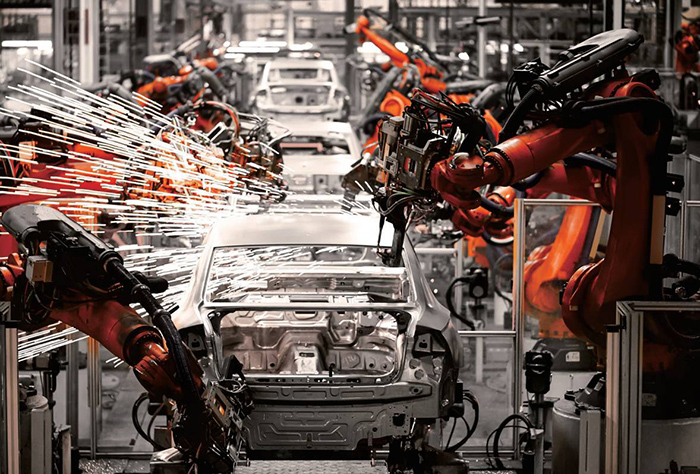

The machine is using the famous brand six-axis robot, the repeat positioning accuracy is high,the trajectory running accuracy is high, and the operation is stable. It is processing at a relatively high speed and precision rate during welding, which greatly result in its effificiency of welding, 2-10 times faster than traditional welding.

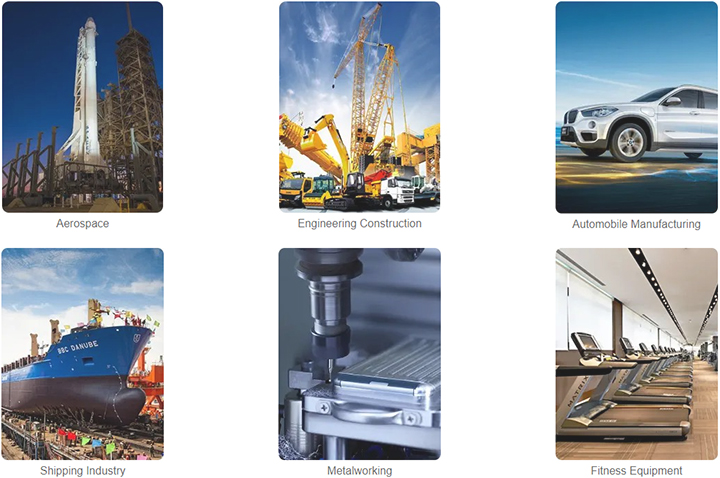

Moreover, it works at a structural and aesthetic welding seam in consistent width and depth, which save time to grind and polish it afterward. With these conditions above,makes it can be widely used in auto parts, electronic communications, chip manufacturing,metal fabrication, aerospace and other industries.

The positioner system, rotary platform and multi-station welding platform tooling system can be confifigured as customer’s requirements..

Advantages Of Fiber Laser Welding Robot

♦ Laser welding is advantaged by low energy consumption, stable energy output, deep weld penetration, small heat-affected zone, small workpiece deformation, and fast welding speed;

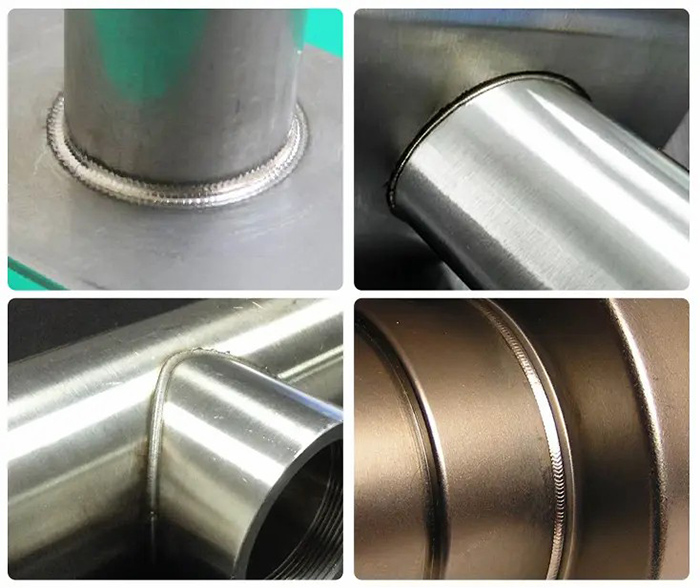

♦ The weld joint is smooth and aesthetically pleasing, with no or simple treatment after welding;

♦ The fiber laser is consumables-free and easy in daily maintenance, with a service life of more over 100,000 hours;

♦ With a high electro-optical conversion rate, it is more energy-efficient and power-saving;

♦ It has a built-in cooling system, requiring no external water supply for cooling;

♦ It adopts the infrared dot-line positioning technology to realize precise programming and welding;

♦ There are two modes of fiber laser welding modes (modulating/continuous), which can be switched as required;

♦ With a protection grade of IP54, the robot can adapt to harsh production conditions;

♦ The robot's repeated positioning accuracy is up to 0.05mm, achieving a stable and reliable performance;

♦ The six-axle robot is more flexible, enabling welding operation in larger space and allowing flexible transmission and non-contact welding for inaccessible precision parts, which is applicable to seam welding, splice welding, butt welding, stitch welding etc.;

♦ A wire feeding device, included in the standard configuration for the whole series, is applicable to larger welds to meet the welding needs of most products;

♦ CCD-based observing system (LCD) is optionally provided to clearly observe the welding effect.

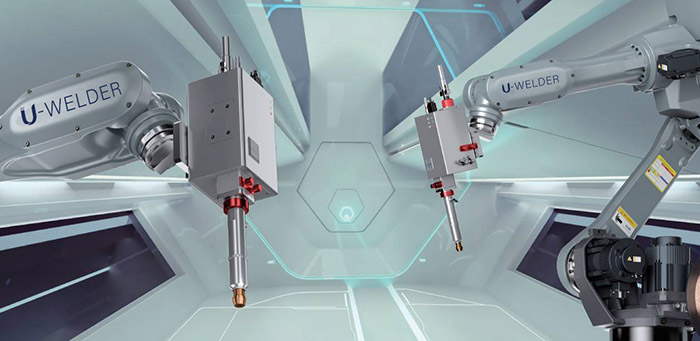

Introduction Of Main Components

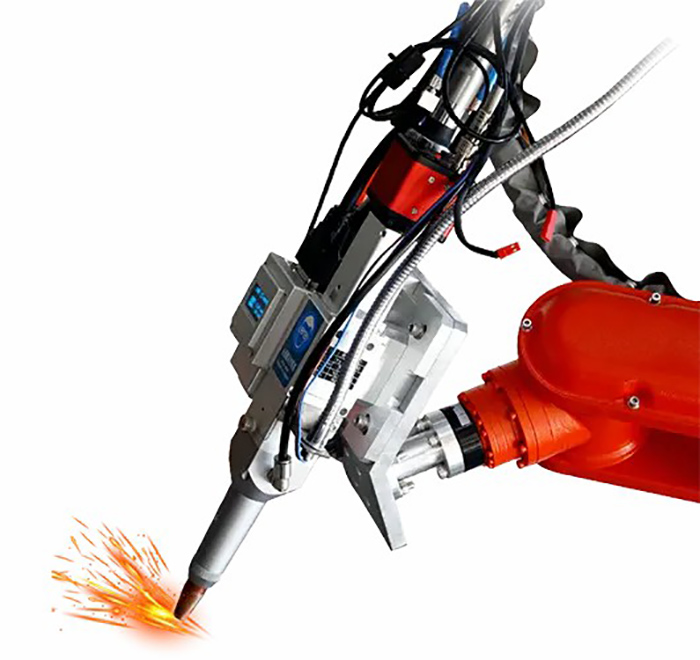

Using self-developed laser welding joint, it has very high welding stability and flexibility, and can rotate and swing 360 degrees for welding

The water tank of robot laser welding machine can heat and cool the machine, and monitor the water temperature in real time.

If the temperature is too high, the system will automatically turn off the laser to avoid damage to the laser.

The control cabinet of the robot laser welding machine supplies the operation energy of the robot arm,

making the equipment more energy-saving and power-saving.

The machine is equipped with intelligent operation handle, the icon is simple and easy to understand,

and the operation can be in place in one step for a few minutes.

The laser host cabinet can clearly observe the product positioning and welding effect according to the red light indication

Double Wedge Swing Welding Joint Technology

The wobble welding module is configured on the laser welding joint. Its unique wedge vibration mode widens the weld and makes the laser welding more widely used. It can realize laser high-efficiency and precision welding for larger workpieces and workpieces with wider weld

Angle Welding Of Complex Products

It has great flexibility to weld the complex parts of seam and stack welding, and it can adapt to the complex parts of seam and stack welding

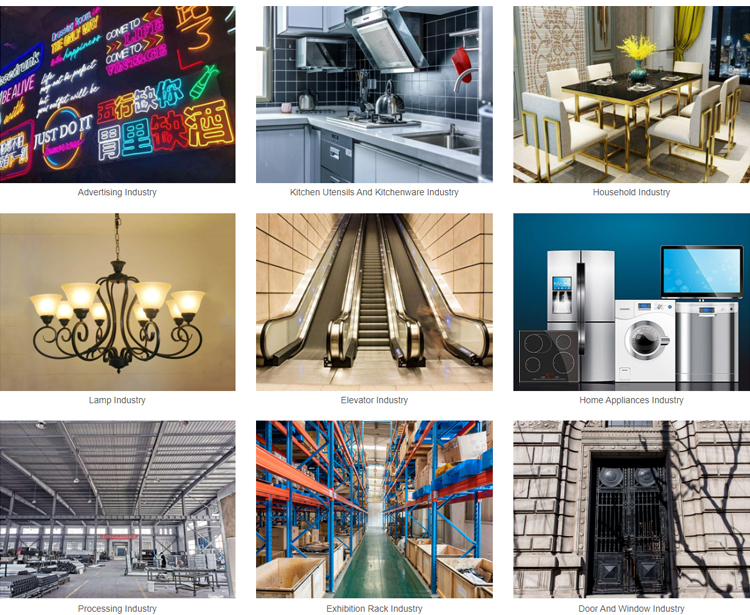

Application Scenarios

Conventional manual welding is disadvantaged by energy consumption, unreliable welding quality and hazard to welding personnel. As a result, enterprises substitute welding robot for conventional manual welding. With the proven application of laser technology, many enterprises use laser welding robot instead of conventional welding robot. One laser welding robot can work as efficiently as 3-4 conventional welding robots together, saving a lot of time on prototyping and investment in tooling, and reducing investment and costs.

Application